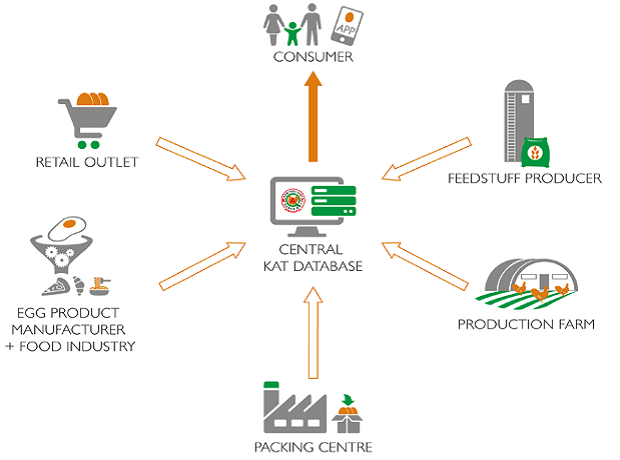

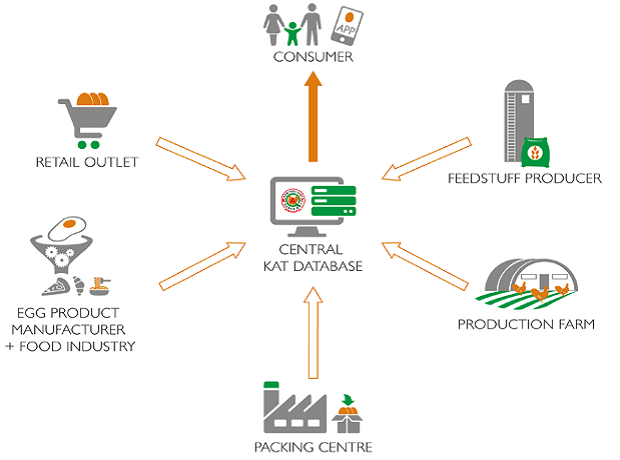

Full traceability from farm to consumer

Over the last decade, transparency and traceability of food, including eggs, has become vital. Since 2005, traceability of eggs from the egg producer until the consumer’s kitchen or the food industry that is using eggs as ingredients, is mandatory under the European Food Law.

Read more

Smooth integration of Aeros and Ovotrack supports US customers

Aeros and Ovotrack have build a solid interface which synchronizes base data about vendors, flocks, housing systems, customers and items into Ovotrack. Kreher’s Family Farms is one of the companies that went live with the Aeros – Ovotrack connection recently.

Read more

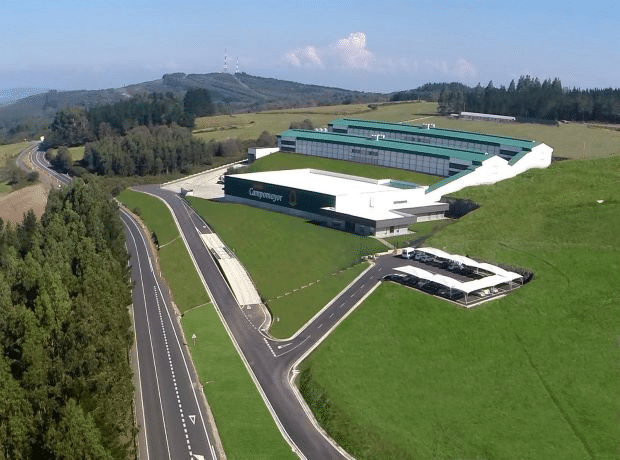

Granja Campomayor in full control using Ovotrack

The Ovotrack Solution at Granja Campomayor is a very comprehensive, as they almost use every single module Ovotrack offers. Ovotrack helps them to get insight in their farms and of course traceability.

Read more

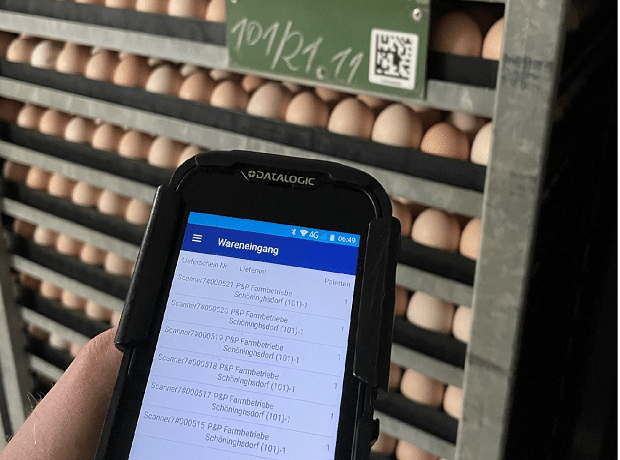

On Farm Scanning (part 2): Chippindale Foods

Ovotrack On Farm Scanning, is used to receive eggs remotely from farms. On Farm Scanning application can be used in different ways and for multiple goals. In this edition (part 2) we will give more insight in the process of Chippindale Foods and how they reduce the waiting time of truck drivers when delivering eggs at the grading center.

Read more

Ovotrack signed a contract with the German company Detlef Coldewey GmbH to take over responsibility for the c2flagranto software that is used by a lot of German egg grading and egg processing companies. Both software solutions integrate very well and a growing number of customers experience the synergy of combining the strength.

Read more

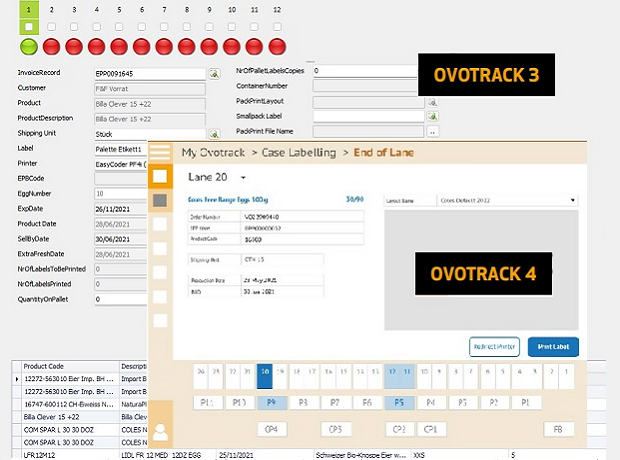

Keeping traceability with Ovotrack software

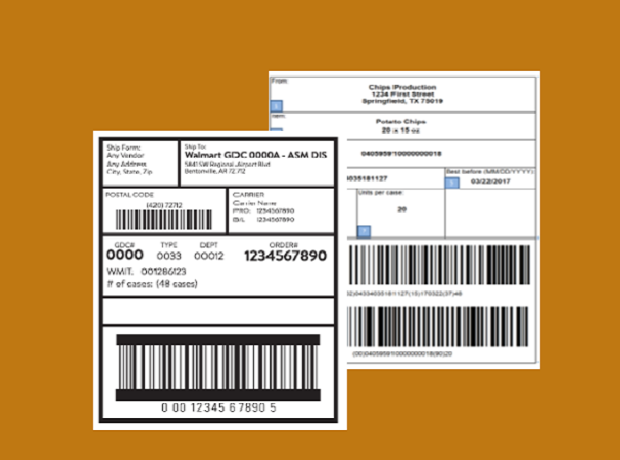

As part of the Ovotrack solution, outer packs with graded eggs will get unique barcodes.

These barcodes are stored in the Ovotrack database with information about the source of the eggs as well as their destination.

Read more

Increasing traceability requirements in Germany

German traceability requirements are on the rise. In the country where the ‘print on egg’ code was introduced first as part of the KAT system, retailers are keen to take traceability to the next level. This resulted in six new Ovotrack customers in Germany.

Read more

Vacancy - Medior Consultant Customer Support

We are hiring! Are you our new Medior Consultant Customer Support? Join our team in Amerongen (NL) and travel the world...

Read more

Recent live projects - new implemantations

We have welcomed various new customers this year and made a lot of new implementations. Each Ovotrack user has its own goals and uses Ovotrack differently. In this article we will explain the goals and reasons to invest in Ovotrack for a couple of these recent implementations.

Read more

MPS Egg Farms, one of the largest egg producers in the USA, is investing in the future of the company in different areas. After recent expansions with egg farms in Texas and Georgia and the introduction of Kipster in the US egg market, MPS Egg Farms decided to invest in the Ovotrack Solution.

Read more

Collecting grading results from grading machine

In the egg packing center, each batch of ungraded eggs is graded on quality, size and weight with an egg grading machine. The Ovotrack software can gather, group and report these grading results.

Read more

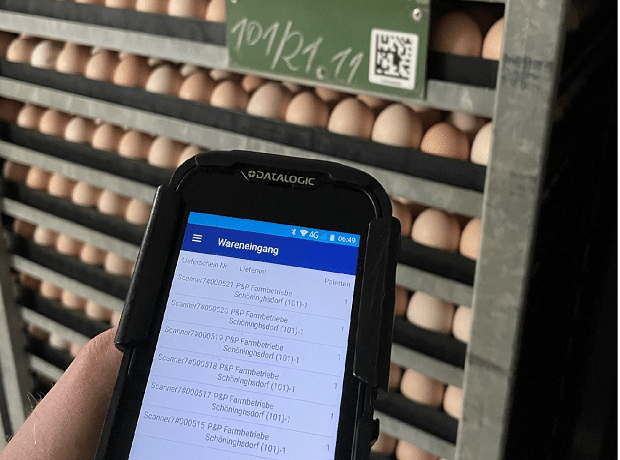

Unique barcode is scanned at the farm

The egg producer puts a label with a unique barcode on every pallet or trolley of ungraded eggs. The driver that collect the eggs, can scan this barcode with a handheld scanner during loading or whilst unloading eggs at the egg packing center.

Read more

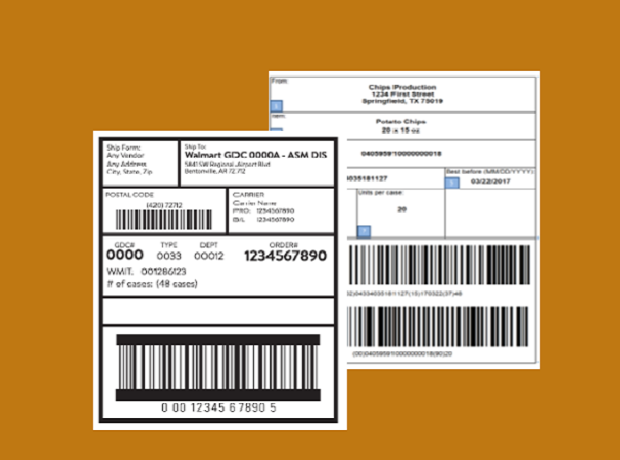

Retailers Walmart and Lidl ask for GS1 pallet labels

In the last couple of weeks, the Ovotrack support departement received customer requests from various countries for new pallet labels. Although customer specific pallet labels are common practice in some countries, it’s new to others.

Read more

Are you a techie at heart, who likes to run his own 'company' within a growing organization? At Ovotrack you will have the opportunity to fulfill a pivotal role in which you are fully responsible for the successful operation of our ICT solutions at customers worldwide. Does this sound like a challenge to you? Then continue to read!

Read more

On Farm Scanning (part 1): Emsland Brüterei

Ovotrack On Farm Scanning, is used to receive eggs remotely from farms. On Farm Scanning application can be used in different ways and for multiple goals. In this article (part 1) we will zoom in on Emsland Brüterei and how to realize real time stock control of hatching eggs at all farms and trucks.

Read more

MPS Egg Farms, one of the largest egg producers in the USA, is investing in the future of the company in different areas. After recent expansions with egg farms in Texas and Georgia and the introduction of Kipster in the US egg market, MPS Egg Farms decided to invest in the Ovotrack Solution.

Read more