Other Modules

Click on the module for more information...

Truck Weights

Connection of truck scale to Ovotrack and distribute weight over all pallets in the truck.

Warnings at Receive

Automatic warning generator for specific quality checks at the receive department.

Ingredient Batches

Create batches of ingredients like salt, sugar or critic acid and connect to a breaker batch.

Traceability, labeling and stock control of egg products

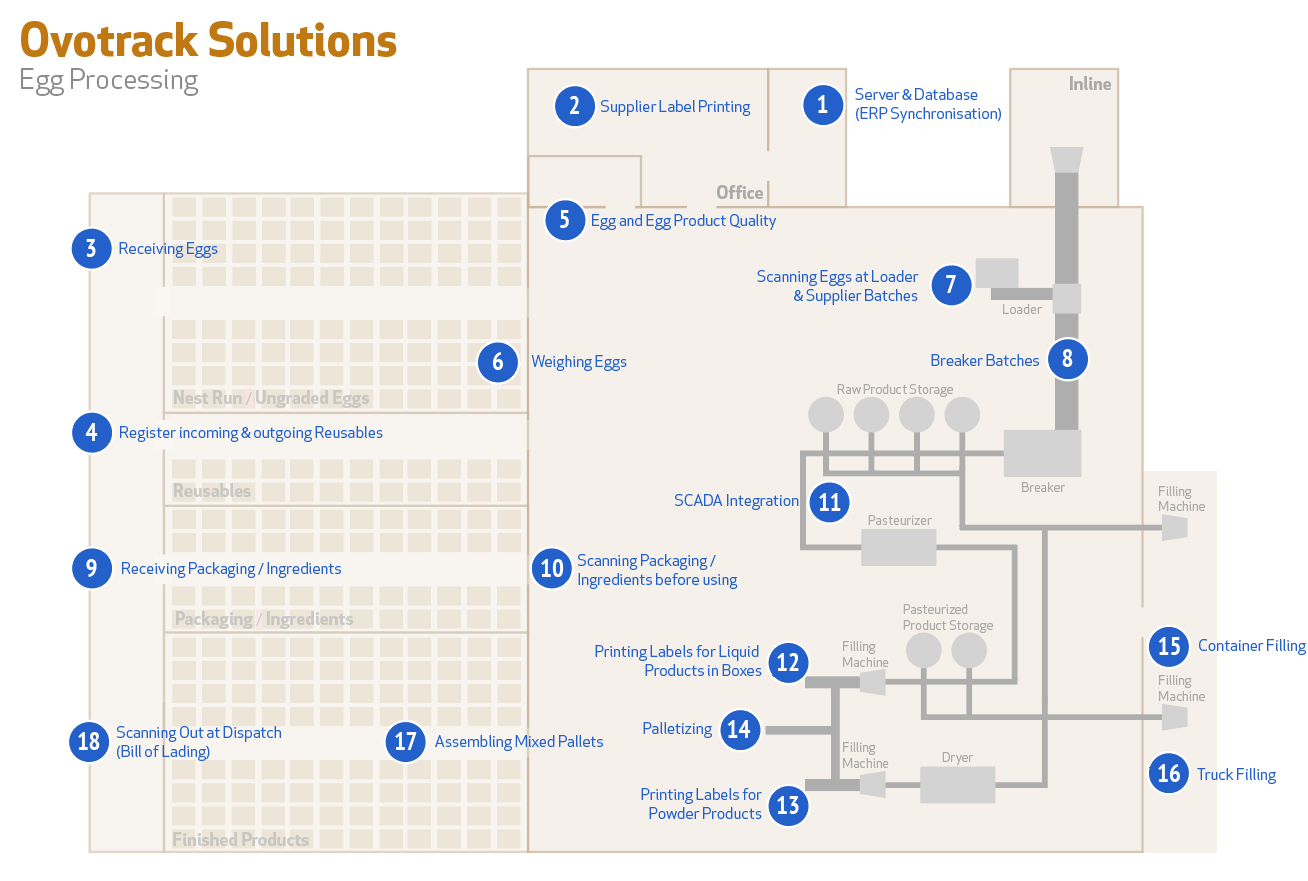

Ovotrack offers a modular solution for all variations of egg processing, such as breaking, pasteurizing, drying, boiling or coloring eggs. Different modules can be implemented at the same time or in several stages. Which module to start with depends on what benefits you want to realize first with the implementation of Ovotrack:

- Receiving and weighing eggs, additives and packaging materials

- Receiving/sending with truck weighing connecting to purchase, sales orders

- Quality control eggs

- Stock control eggs

- Easy data entry with scanner at the breaking machine

- Automation of batch changes on the loader of the breaker

- Collecting and reporting breaking results per delivery and/or period

- Connecting ERP systems with the work floor of the breaking plant

- Labeling finished products (bag-in-box, pallecons, etc.) in conformity with customer requirements

- Control on production and best before dates per customer

- Get better insight by collecting breaking results

- Stock control of packaging material

- Traceability of empty material

- Improving breaker planning

- Automated traceability of egg products

- Better control on the labeling of finished products

- Stock control finished products