On Farm Scanning (part 2): Chippindale Foods

No waiting time for truck drivers

On Farm Scanning in practice

As every single customer is unique, the On Farm Scanning application can be used in different ways and for multiple goals. In this series of news article we want to show you how three different customers are using the On Farm Scanning application in different ways. In the previous edition, we dived into the process of Emsland Brüeterei and their benefit of having real-time stock control of hatching eggs at all farms and trucks.

In this edition (part 2) we will give more insight in the process of Chippindale Foods. One of their benefits of using Ovotrack On Farm Scanning is to reduce the waiting time of truck drivers when delivering eggs at the grading center.

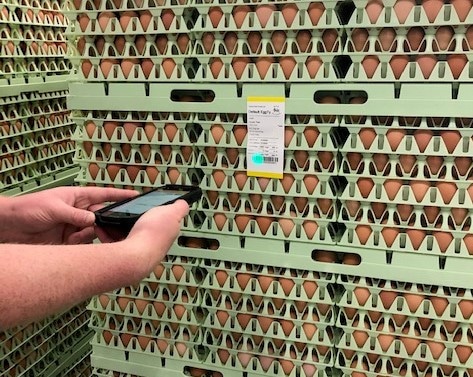

Registering eggs at the farm by the truck drivers

Chippindale Foods handles more than six million eggs a week and supplies retailers and service outlets all over the country.

Benefits for Chippindale Foods:

- Insight in ungraded eggs that are coming to the grading plant.

- Time savings at the receive door of the grading plant.

- No waiting time for truck drivers when delivering ungraded eggs.