Breaker Batches

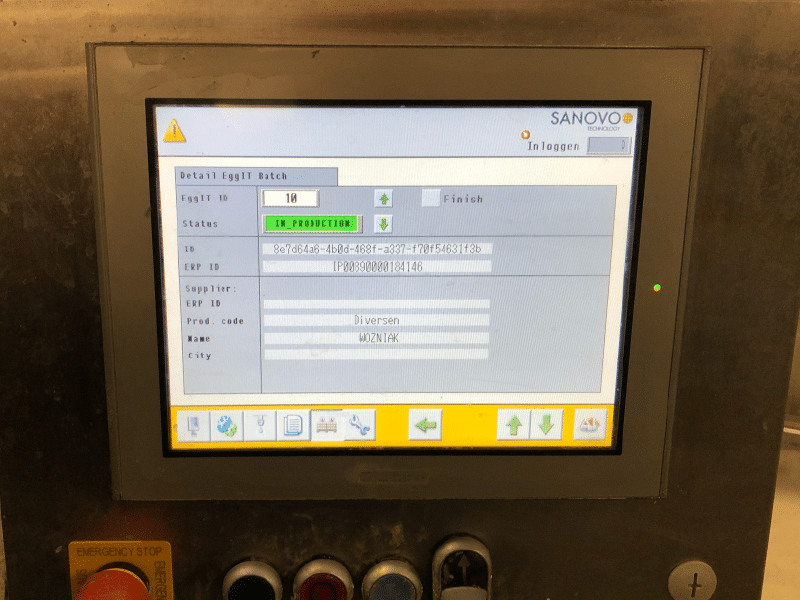

If the breaking machine supports communication, an Ovotrack Loader PC will be installed at the loader to enable communication. After scanning the label, the required information can be forwarded to the breaker, such as supplier name, quantity eggs and the date of lay. The breaking machine uses this data to create a new batch. At the end of the batch the breaking machine will send the breaking results back to Ovotrack, such as quantity whole eggs and quantity of empty cups.

After scanning the label, the exact moment of batch change has to be signaled on the breaking machine with help of the RFID egg. Thanks to this automatic batch change, the loader does not have to run empty to capture the exact breaking results, so there won't be any production loss.

Take a look at the other software modules for Egg Processing

DURING PROCESSING

AFTER PROCESSING